Plantes médicinales: le must des Balkans

Suivez nos aventures en recevant notre newsletter toutes les semaines, inscrivez-vous en cliquant ici puis renseignez votre nom et email.

Pëce, 5 juillet 202

A 25 kilomètres de Pëce, au pied des montagnes du parc national de Prokletije alt. max 2700m, nous avons la chance de visiter Agroproduct SH.P.K. Fondée en 2002 par Halit Avdijaj de retour d’un exil de 18 ans en Suisse alémanique.

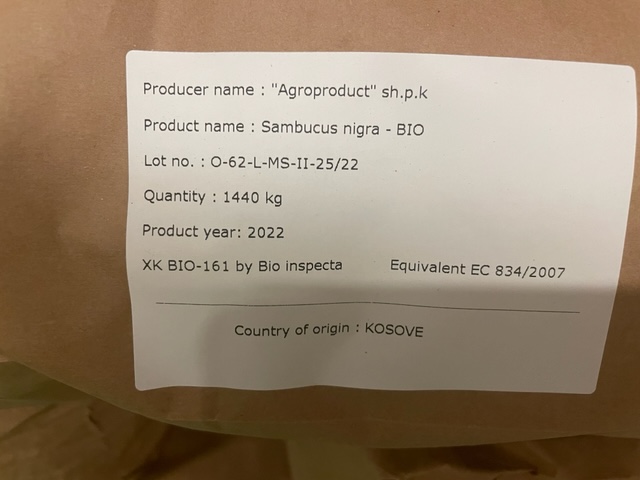

Son idée: dans un Kosovo décimé par la guerre, construire un réseau de cultivateurs et cueilleurs afin d’assurer un revenu à des communautés agricoles locales. 20 ans après, 3200 producteurs, cueilleurs sont affiliés à Agroproduct. 270 hectares sous contrats , dont 100 hectares en culture directe. Nos découvrons une qualité de produits « bio » jamais vue à un échelon industriel vendue aux industriels suisses et allemands.

20 ans de développements incessants

La réussite d’Agroproduct résulte de la vision et de l’engagement de son fondateur Halit qui a construit un flux totalement maîtrisé entre la production de semences, jusqu’à la livraison en gros aux clients (600 tonnes de produits bruts exportés, prêts à l’emploi (Tisanes, cosmétique condimentaires).

Contrats à long terme avec les producteurs et cueilleurs, processus qualité, processus de récolte, formations des cueilleurs, rien n’est laissé au hasard. Toutes les certifications pour assurer une production durable, bio, sont suivies et actualisées. En cas d’accident, (de détection de pesticides sur une récolte), la récolte est isolée du flux, déclassée et traitée dans des bâtiments et machines à part, pour éviter toute contamination. Les machines de traitement des plantes (Nettoyages – tris) sont développées et améliorées en permanence par une société serbe Euro Prima, et d’autres industriels balkaniques. Nous avons assisté au tri des primevères, avec finition manuelle et au nettoyage des camomilles. (Séchées avec les tiges et passées en machine). Le résultat est impeccable. le flux des plantes est totalement maîtrisé dans un soucis d’économie de mouvements et de temps.

Le séchage et la collecte clés du succès

L’organisation d’Agroproduct est basée sur la qualité des produits, elle est donc décentralisée à la différence de tout ce que nous avons vu jusqu’à présent. 58 centres de collectes, première étape de contrôle qualité de la matière fraîche alimentent 5 centres de séchage dont celui d’Istog qui fonctionne comme navire amiral et centre de séchage local. Les 5 centres sont répartis dans tout le pays, les plantes ne doivent pas avoir le temps de fermenter durant le transport qui doit être le plus court possible. Les séchoirs sont des chambres de type frigorifiques dotées de planchers perméables dans lesquels est injecté de l’air chaud (chauffage aux pellets.

L’air chaud va déshydrater les plantes en 15-20 heures suivant les végétaux, stockés sur 15-20 cm de hauteur. la qualité devient uniforme pour un type de plantes, qui sont stockées avec leurs tiges dans des sacs de 100 litres en attente de l’émondage. l’émondage est assuré à Istog, par une équipe fidèle depuis des années, leur salaires est de 20% supérieur à celui du marché, un restaurant d’entreprise est offert, faisant partie des avantages en natures offert par l’entreprise. Conditions d’hygiène irréprochable. Le prix payé aux producteurs est lié au prix des marchés, il est déterminé annuellement par type de plantes.

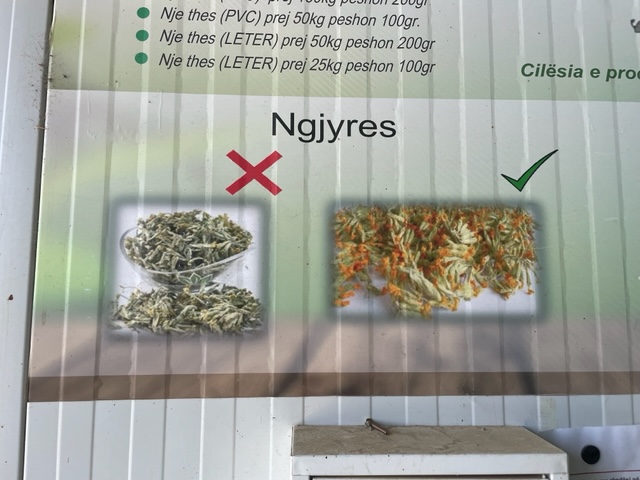

Le contrôle qualité c’est une démarche permanente

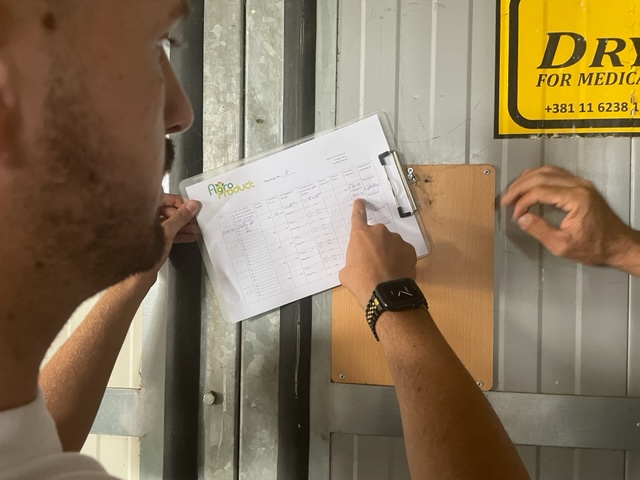

Au fil de la visite des installations, nous rencontrons les documents de contrôle qualité collés aux portes des locaux techniques. Sur un séchoir, pas moins de 11 critères pour « tracer » les lots en cours de séchage, tout est numéroté, daté, durée de séchage etc…

Le BIO est certifié pour 95% des plantes. Toujours à la recherche de producteurs BIO, Agroproduct demande une distance de minimum 1 à 2 kilomètres entre les parcelles de plantes médicinales et les cultures conventionnelles alentour.

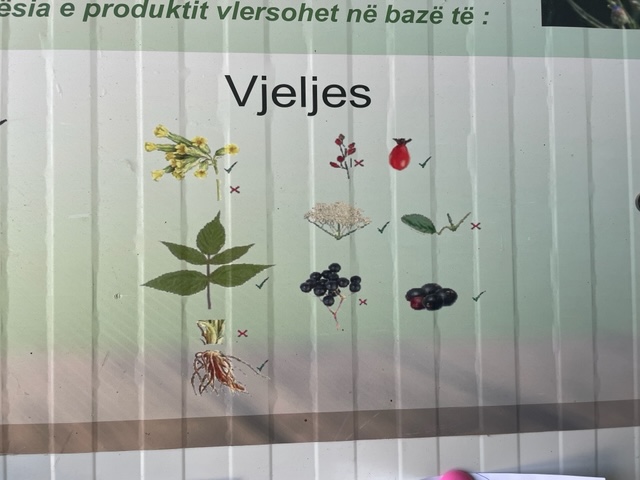

Pour la cueillette, également des documents très complets, processus expliqués à base de photos sur ce qu’il faut faire ou non. L’entreprise se fait conseiller par le plus grands spécialiste en botanique du Kosovo, Fadil Millaku, docteur en biologie et botanique et professeur.

Les semences sont produites par l’entreprise, ainsi que les jeunes plants afin de garantir pour les productions internes et externes une qualité de végétale homogène. Ici la serre de multiplication avec son automate à brumisation qui parcours toute la longueur du tunnel selon la météo afin de garantir une humidité des feuillages.

La famille au centre de l’activité

La discussion avec Fatbardha Avdijaj, fille du fondateur, en charge des relations publiques et du contrôle qualité et Arber Avdijaj, fils du fondateur en charge de la production, des ventes et de résoudre tous les problèmes, nous démontre que nous avons à faire à une entreprise ultra compétente.

Nous sommes sur les mêmes critères qualitatifs, par exemple les stades de maturité des floraisons et une multitude de points qui font la différence entre un produit de qualité vendu cher dans une Europe du Nord exigeante, et d’autres marchés qui ne sont pas la préoccupation de l’entreprise. Le fondateur a pris du recul sur l’opérationnel confié à la jeune génération qui ne dit pas avoir plus de 30 ans, diplômés dans tous les domaines liés à l’activité. L’entreprise est présente sur les grandes foires internationales pour fidéliser ses clients et en rencontrer de nouveaux. Pour convaincre les nouveaux , une seule technique, un stage de 5 jours sur l’ensemble du territoire kosovar, à livre ouvert, pour démontrer par l’opérationnel, le soin apporté aux produits. Pas de culte de la personnalité, pas de dorure, la famille est sur le terrain, les téléphones sonnent dans tous les sens, ils sont disponibles pour nous alors que nous n’étions pas annoncés. Bel exemple d’engagement!

L’Europe comme sponsor.

De nombreux équipements sont cofinancés par les différentes institutions européennes privées ou publiques, investissement contrôlés en permanence sur le terrain. Comme chez nos amis producteurs de myrtilles, »Boronica » en albanais, Caritas est très présente sur le terrain et assure les contrôles des investissements qui sont rarement en cash et pratiquement toujours en nature. (Machines – semences, jeunes plants). L’entreprise joue également la carte de l’Europe ne multipliant les partenariats stratégiques; le transport est par exemple confié à une entreprise serbe et une entreprise kosovar.

Un exemple pour les jeunes kosovars dont beaucoup pensent toujours à quitter le pays

Un terrain, un climat, des terres, de l’eau à profusion, une main d’œuvre concurrentielle au niveau européen, une automatisation des processus de culture comparable au niveau de l’Europe du Nord, un processus logistique totalement maîtrisé, Agro Product devrait stimulé les jeunes qui pensent que rien ne va au Kosovo et que l’herbe est plus verte ailleurs, au Nord!!